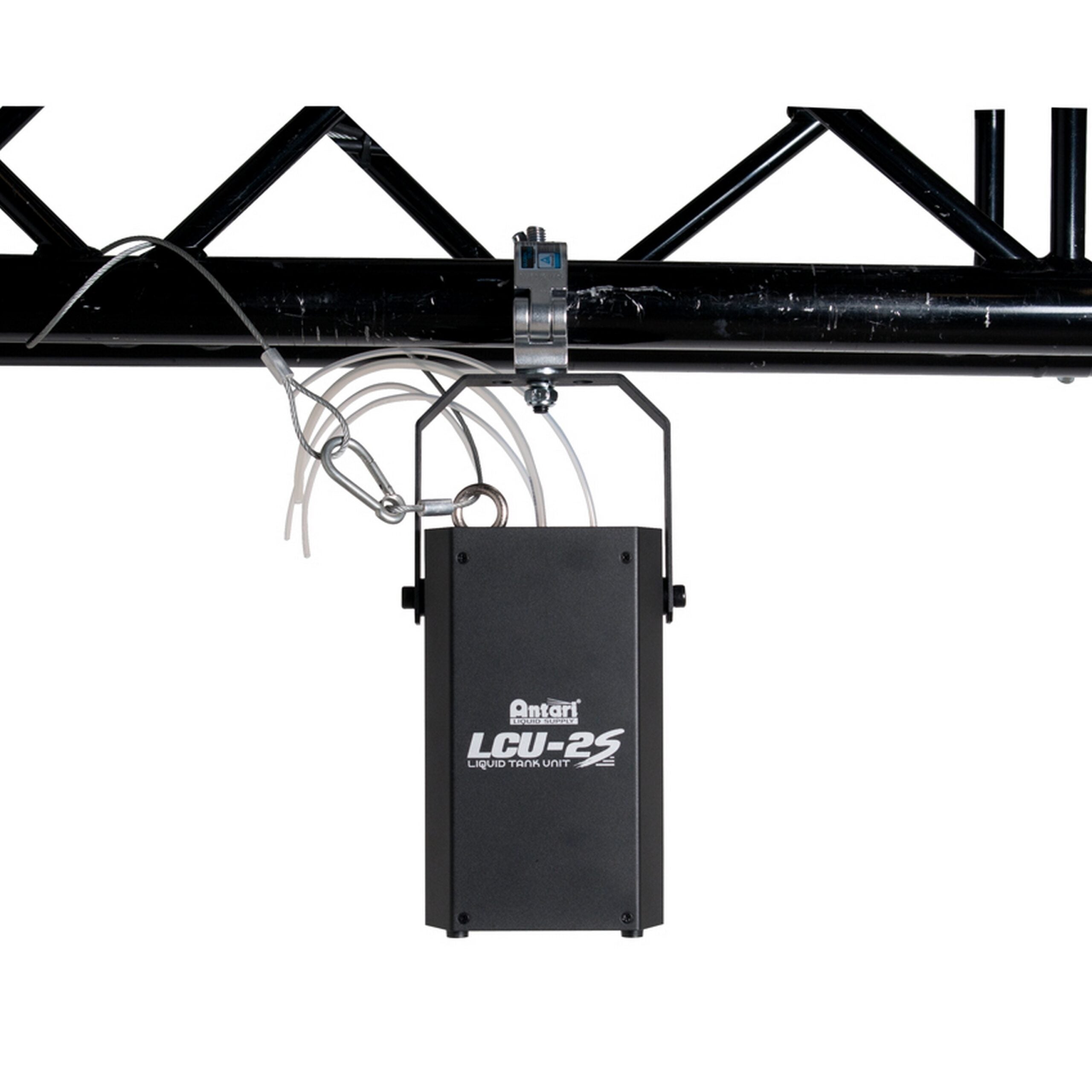

The Antari LCU - 2S is an all - in - one universal liquid delivery system designed for high - volume use with Antari foggers, fazers, and snow machines. It can simultaneously supply up to 3 different Antari effect machines that use the same type of effect liquid. This system consists of two key parts: a separate Liquid Supply Unit and a Liquid Tank Unit. The Liquid Supply Unit has 3 4mm liquid tube outputs, 1 6mm liquid tube input, a 3 - pin data control input, an adjustable yoke bracket, and a safety cable loop for easy clamp or truss mounting. The Liquid Tank Unit features 1 6mm liquid tube output, 1 3 - pin data control output, and a main power switch. Included with the system are essential accessories such as a 3 - pin data connection cable, 6mm and 4mm fluid tubes, 3 4mm - 4mm adaptors, 3 6mm - 4mm adaptors, a fluid filter, and a power cord. You can place the Liquid Tank Unit anywhere convenient, like near the main liquid supply container. It automatically pumps liquid from any - sized container directly to the Liquid Supply Unit, eliminating the need for ladders or scissor lifts to refill effect machine liquid containers. The maximum vertical distance between the two units is 40 feet (12m), and the maximum horizontal distance is 115 feet (35m). Simply power on the Liquid Tank Unit, and it will continuously supply effect liquid to the Liquid Supply Unit, ensuring that the liquid tanks of up to 3 Antari effect machines are always full. Key features include its universality for Antari effect liquid delivery, separate units for easy setup, continuous liquid supply, support for all Antari fogger, fazer, and snow machine models, and long - distance liquid transfer capabilities. Technical specs: The Liquid Tank Unit has a power switch, 3 - pin data control output, 6mm liquid tube input and output, and IEC power input. It measures 6.22” (158mm) in length, 4.06” (103mm) in width, 9.76” (248mm) in vertical height, and weighs 3.97 lbs. (1.8 kg). It operates on AC 100 - 120V 50/60Hz 0.35A with a maximum power consumption of 48W and a T0.8A 250V fuse. The operating temperature range is 5 °C - 40 °C (41 °F - 104 °F). The Liquid Supply Unit has a 3 - pin data control input, 1 6mm liquid tube input, and 3 4mm liquid tube outputs. It measures 7.05” (179mm) in length, 6.57” (167mm) in width, 3.31” (84mm) in vertical height, and weighs 4.30 lbs. (1.95 kg). Accessories include 40 feet (12m) of 6mm tubing, 32.8 feet (10m) of 3 - pin control data cable, and 6.6 feet (2m) of IEC power cable.

Using the Antari LCU - 2S Liquid Control System is a breeze. First, find a convenient spot for the Liquid Tank Unit, preferably close to the main liquid supply container. Connect the 6mm liquid tube from the main container to the input of the Liquid Tank Unit. Then, connect the 6mm liquid tube output of the Liquid Tank Unit to the 6mm input of the Liquid Supply Unit. Attach the 3 - pin data connection cable between the two units for seamless communication. Next, connect the 4mm liquid tubes from the Liquid Supply Unit to the Antari effect machines you want to supply. You can connect up to 3 machines that use the same type of effect liquid. Once all the connections are made, plug in the power cord of the Liquid Tank Unit. Turn on the main power switch on the Liquid Tank Unit. The system will start automatically pumping liquid from the main container to the Liquid Supply Unit, which in turn will keep the liquid tanks of your Antari effect machines full. As for maintenance, regularly check the fluid filter to ensure it's clean. If it's dirty, replace it according to the manufacturer's instructions. Also, make sure all the tubes and connections are secure and free of leaks. When not in use, store the system in a dry place at a temperature between 5 °C and 40 °C (41 °F - 104 °F). And always use the correct type of effect liquid recommended by Antari to avoid any damage to the system.